- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

DFC-3000

DOYA

8456110090

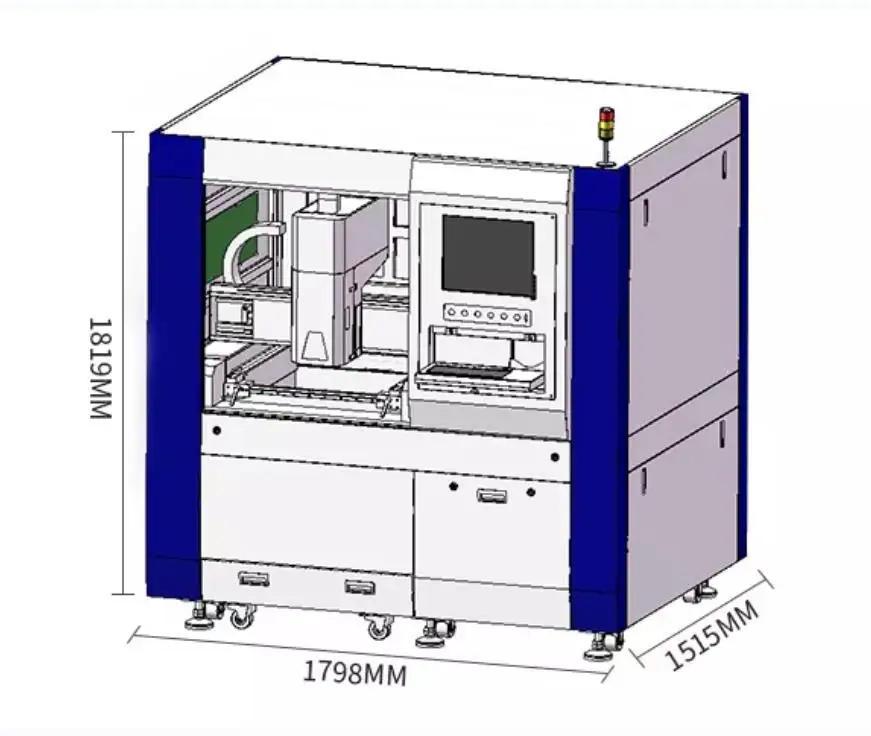

Laser power: 1000W 1500W 2000W 3000W

Laser source brand: Max/Raycus/Jpt/Reci(optional)

Working area: 400x200mm / 600x600mm / 600x800mm

Cooling system:air cooling

Application:stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum- plating zinc plate, copper and other metals.

Features:

1. Less friction provides greater performance for cutting accuracy and speed.

2. Stable running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours.

3. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

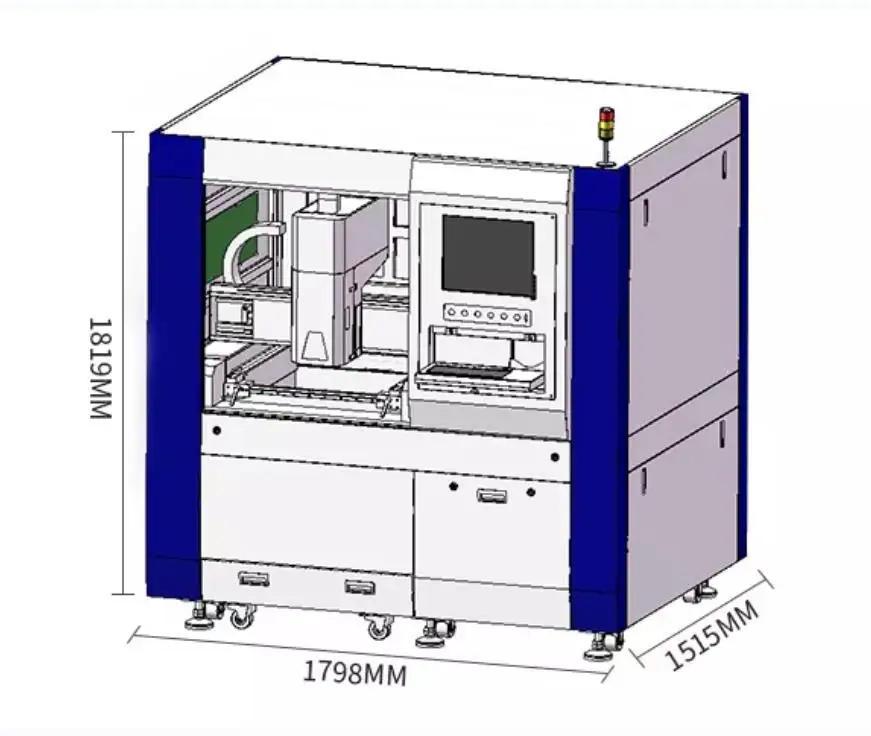

| Model | DY-QCW-4020F |

| Working area | 400x600mm |

| Laser source | JPT QCW-150W |

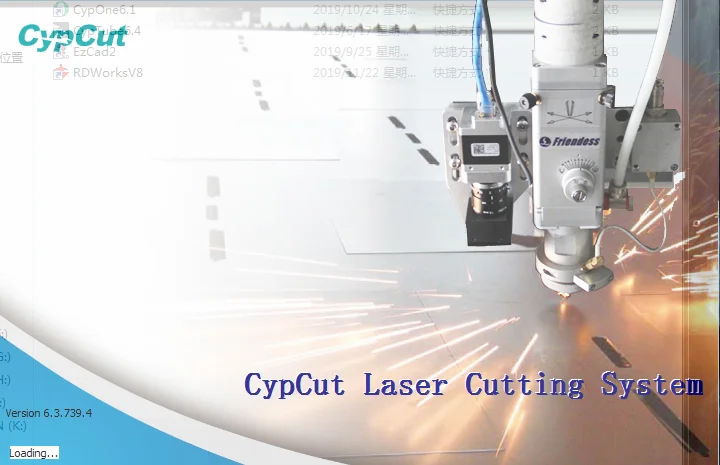

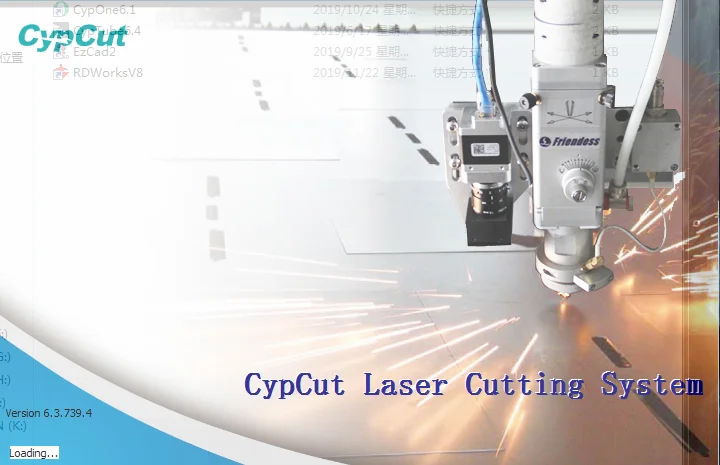

| Control system | PC control with Cypcut |

| Drive system | Panasonic from Japan |

| Laser head | Raytools laser head from Switzerland |

| Transom | Aluminum transom |

| Transmission | TBI screw |

| Guide rail | PMI from Japan |

| Cooling chiller | HANLI OR S&A water cooling system |

| Min line width | ≤0.02mm |

| Position accuracy | 0.1mm |

| Cutting speed | 45-60m/min |

| Control software | CypCut |

| Graphic format support | PLT, DXF, BMP, JPG, AI,ect |

| Working environment | 0-45℃ |

| Operating Humidity | 5-95% |

| Nominal Average Output Power | QCW: 150W |

| Maximum Peak Power | 1500W |

| Maximum Pulse Energy | 15J |

| Repeat Frequency | 1 ~10000Hz (Rated Output Power) |

| Pulse Width | 0.01~10ms (Rated Output Power) |

| Beam Parameter Product | ≤4.5 @100um mm*mrad |

| Central Wavelength | 1080nm |

| Spectral Width@3db | <4nm |

| Armored Cable Length | 5m |

| Cooling Method | Air Cooled |

| Operating Voltage | Single-phase 220 (AC)V |

| Maximum Power Consumption | 1.1kW |

| Operation Temperature | 10 ~ 40℃ |

| Storage Temperature | -20~ 50℃ |

Different thickness choose suitable laser power

Integrated laser cutting special function module, powerful function, good man-machine interface, simple operation, easy to learn and understand. Compatible with a variety of CAD, DXF, AI, IGS drawing formats, intelligent discharging and saves costs, automatic cutting path matching saves processing time.

Professional industrial computer

Double-temperature dual-control high-precision water-cooling machine 800WDR is selected. The machine is mainly composedof compressor, condenser, high-purity water circulation system, deionization device, temperature control board andelectric control board.

The water circulation system is equipped with low-temperature water and normal temperaturewater. Group cooling water,dual temperature dual controlto meet the needs of fiberlaser constant temperature.

| Gas Type | Pressure | Purity |

| O2 | 1MPA | 99.6% |

| N2 | 2.5MPA | 99.9% |

| The higher purity is, the better cutting quality will be. | ||

Laser power: 1000W 1500W 2000W 3000W

Laser source brand: Max/Raycus/Jpt/Reci(optional)

Working area: 400x200mm / 600x600mm / 600x800mm

Cooling system:air cooling

Application:stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum- plating zinc plate, copper and other metals.

Features:

1. Less friction provides greater performance for cutting accuracy and speed.

2. Stable running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours.

3. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

| Model | DY-QCW-4020F |

| Working area | 400x600mm |

| Laser source | JPT QCW-150W |

| Control system | PC control with Cypcut |

| Drive system | Panasonic from Japan |

| Laser head | Raytools laser head from Switzerland |

| Transom | Aluminum transom |

| Transmission | TBI screw |

| Guide rail | PMI from Japan |

| Cooling chiller | HANLI OR S&A water cooling system |

| Min line width | ≤0.02mm |

| Position accuracy | 0.1mm |

| Cutting speed | 45-60m/min |

| Control software | CypCut |

| Graphic format support | PLT, DXF, BMP, JPG, AI,ect |

| Working environment | 0-45℃ |

| Operating Humidity | 5-95% |

| Nominal Average Output Power | QCW: 150W |

| Maximum Peak Power | 1500W |

| Maximum Pulse Energy | 15J |

| Repeat Frequency | 1 ~10000Hz (Rated Output Power) |

| Pulse Width | 0.01~10ms (Rated Output Power) |

| Beam Parameter Product | ≤4.5 @100um mm*mrad |

| Central Wavelength | 1080nm |

| Spectral Width@3db | <4nm |

| Armored Cable Length | 5m |

| Cooling Method | Air Cooled |

| Operating Voltage | Single-phase 220 (AC)V |

| Maximum Power Consumption | 1.1kW |

| Operation Temperature | 10 ~ 40℃ |

| Storage Temperature | -20~ 50℃ |

Different thickness choose suitable laser power

Integrated laser cutting special function module, powerful function, good man-machine interface, simple operation, easy to learn and understand. Compatible with a variety of CAD, DXF, AI, IGS drawing formats, intelligent discharging and saves costs, automatic cutting path matching saves processing time.

Professional industrial computer

Double-temperature dual-control high-precision water-cooling machine 800WDR is selected. The machine is mainly composedof compressor, condenser, high-purity water circulation system, deionization device, temperature control board andelectric control board.

The water circulation system is equipped with low-temperature water and normal temperaturewater. Group cooling water,dual temperature dual controlto meet the needs of fiberlaser constant temperature.

| Gas Type | Pressure | Purity |

| O2 | 1MPA | 99.6% |

| N2 | 2.5MPA | 99.9% |

| The higher purity is, the better cutting quality will be. | ||