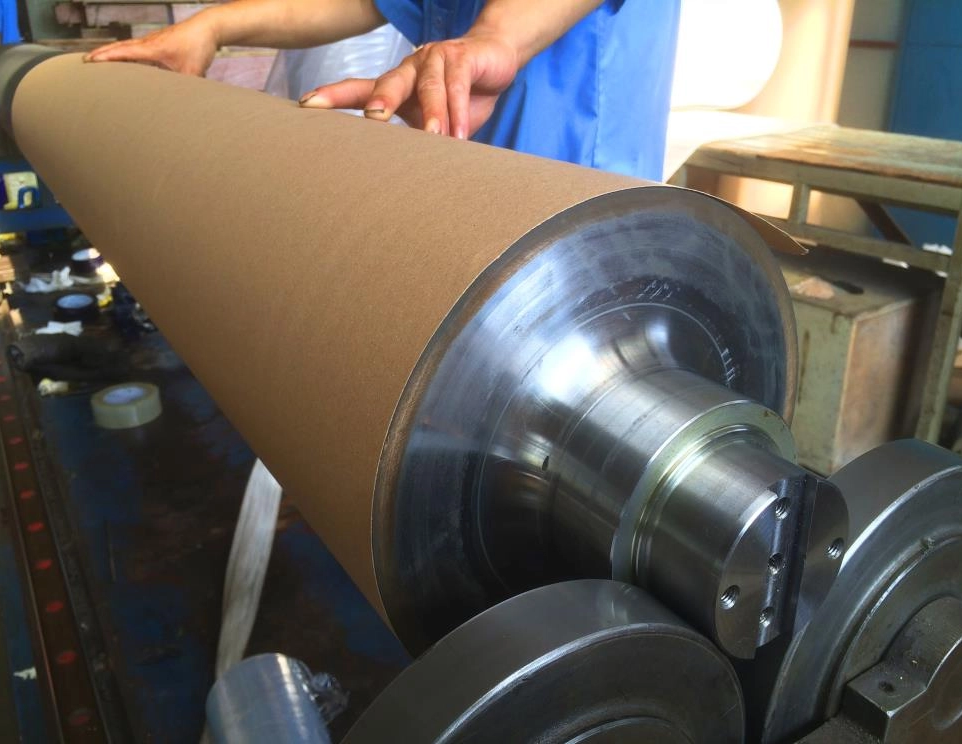

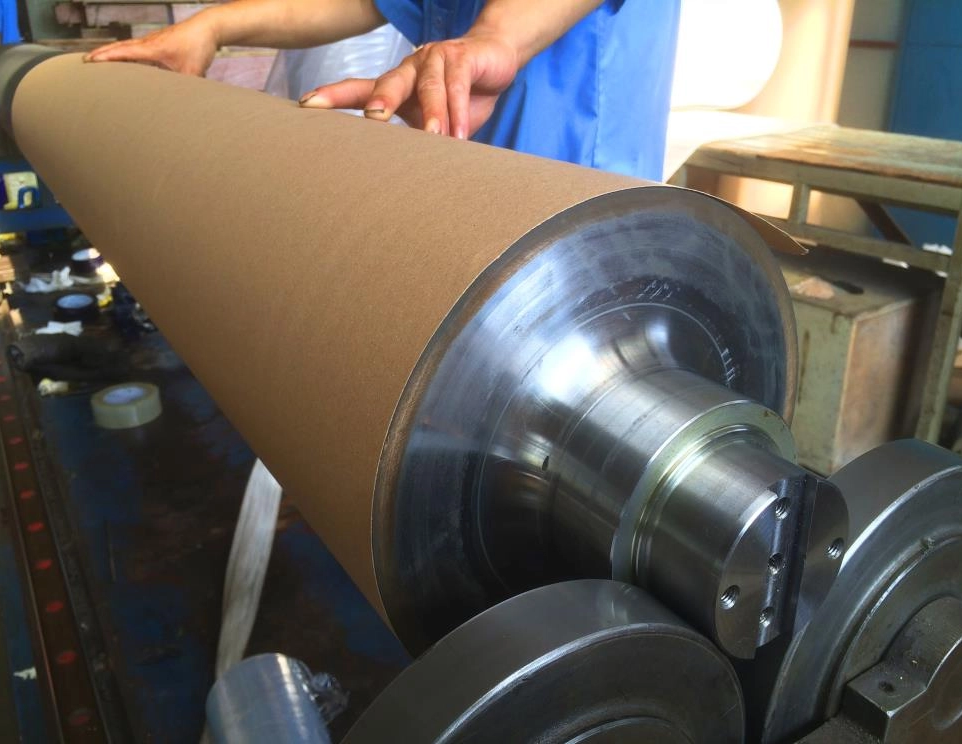

28-02-2026 Ceramic and metal anilox rolls are high-tech products and very expensive precision core components of flexographic printing equipment. They feature high dimensional accuracy, geometric and positional accuracy, surface roughness, and dynamic balance accuracy. Therefore, this specification for the installation, maintenance and care of ceramic and metal anilox rolls is specially formulated. All flexographic printing positions are required to strictly implement and accurately operate in accordance with this specification. Proper, timely and scientific daily maintenance of ink-transferring anilox rolls can prevent roller damage, extend their service life, and achieve stable and high-quality printing results.

Read More

30-01-2026 As the global manufacturing industry places increasingly stringent demands on environmental protection, efficiency and precision, laser cleaning—an innovative non-contact, pollution-free and high-precision surface treatment technology—is ushering in a green revolution for the traditional wood products industry. Studies have shown that precise control of laser parameters (e.g., wavelength, power, pulse width) enables the effective removal of contaminants such as paint, glue, stains and mold from wood surfaces without damaging the wood substrate. This technology is particularly suitable for the restoration of exquisite wood veneers, complex carved components and cultural relics. Additionally, laser surface treatment can be applied to wood surfaces to alter their color, improve surface wettability, enhance the performance of surface coating materials, and boost anti-corrosion and anti-mold properties. Looking ahead, with the integration of intelligent technologies such as beam shaping, ad

Read More

15-01-2026 The ink blocking the cells affects the printing quality, which is a pain point that the flexo printing industry has been difficult to solve. The anilox rollers that have been working for a long time, in addition to part of the damage caused by wear and tear, will also be scrapped due to the reduced cell volume, which affects the printing efficiency and quality. Deep cleaning at least 1-2 times a year will restore the anilox roller as new, prolong the service life of the anilox roller, improve printing quality, and reduce ink loss.

Read More

31-12-2025 Achieving stable, high-quality laser cutting depends on more than just power, speed, or focus settings. One of the most easily overlooked yet crucial factors is coaxial alignment—the alignment of the laser beam center with the nozzle center. Poor coaxial alignment can lead to inconsistent cuts, excessive slag, kerf offset, and even frequent nozzle damage.

Read More