- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

DFC-3000

DOYA

8456110090

Laser power: 1500W 2000W 3000W 6000W 8000W 10000W 12000W 20000W

Laser source brand:Max/Raycus/Jpt/Reci(optional)

Cooling system:water cooling

Application:stainless steel plates, carbon steel plates, galvanized sheets, ect

Features:

1. Support groove cutting, double chuck clamping, suitable for all kinds of irregular pipe fittings.

2. Flexible track is rough to steel pipe and has strong adaptability to deformation. Highly integrated.long service life, high efficiency and energy saving design can greatly save costs.

3. Set cutting plate, cutting pipe as one, can process all kinds of metal materials and all kindsof pipe fitting plate; Full intelligent CNC system, simple operation.

| Fiber Laser source | BWT / MAX laser source |

| Machine body | Plate welding machine bed with Heat-treatment |

| Laser Head | Raytools / Ospri laser head Autofocus |

| Motors and Drivers | Yaskawa |

| Reducer | Shimpo |

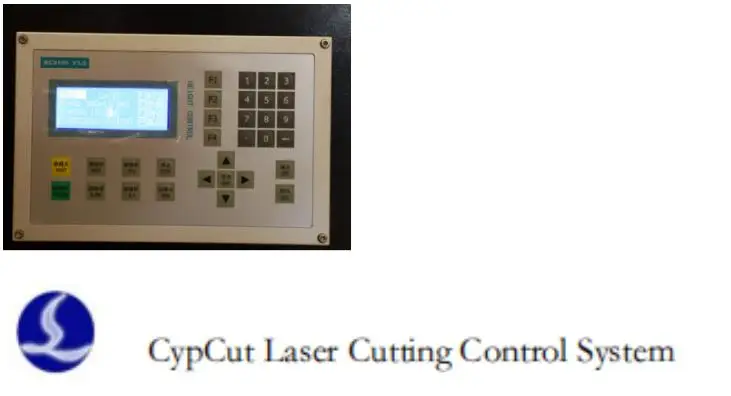

| System | FSCUT 3000S + CYPCUT software + Industrial CPU |

| Air control | SMC |

| Guide rail | HIWIN |

| Rack & pinion | Taiwan YYC |

| Water chiller | Hanli / S&A |

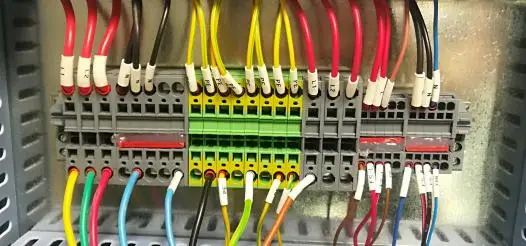

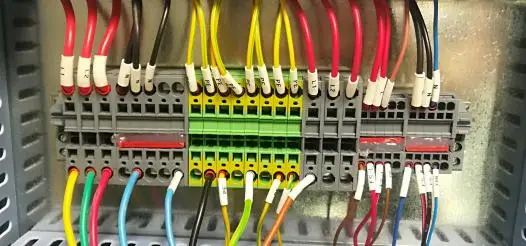

| Electrical components | Schneider |

| Transmission system | Dual-drive, precise rack and pinion |

| Exhaust fan | Included |

| Material | 3000W | Auxiliary gas |

| SS plate | ≤10 mm | Nitrogen |

| Carbon steel plate | ≤20 mm | Oxygen |

| Aluminum | ≤8 mm | Nitrogen |

| Brass | ≤6 mm | Nitrogen |

| Material | 3000W | Auxiliary gas |

| SS tube | ≤6 mm | Nitrogen |

| Iron tube | ≤10 mm | Oxygen |

| Aluminum tube | ≤6 mm | Nitrogen |

| Cutting range | 3000*2000mm / 4000*2000mm / 6000*2500mm |

| Laser power | 1500W / 2000W / 3000W / 6000W / 12000W |

| X/Y axis Repeated Position Precision | ±0.02mm |

| Max. Running Speed | 100r/min |

| Max. accelerated speed | 1.0G |

| Max. Load on working table | 800 KGS |

| Voltage | 3PHASE, 380V |

| Frequency | 50Hz/60Hz |

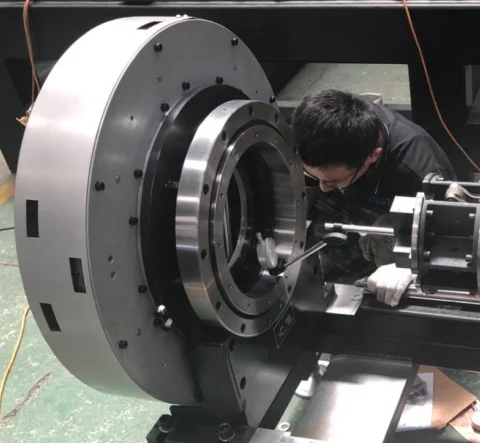

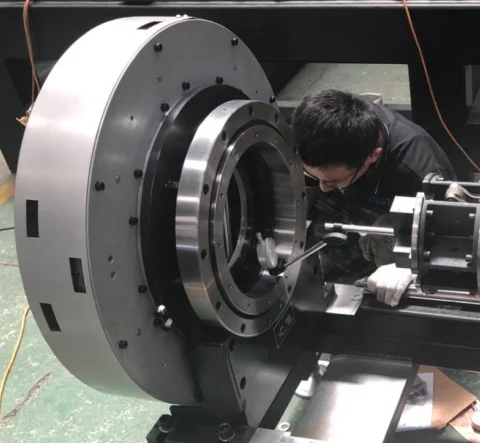

Durable pneumatic chuck enables high clamping accuracy, strong clamping force and stable performance.

We have milling machine in our factory for elaborate process of machine bed and parts in short time with great precision control.

Every machine body need to go through the 800 degree high-temperature quenching to make the machine body strong and stable, which is used by most reputational laser manufactory, such as TRUMPF, Trotec etc.

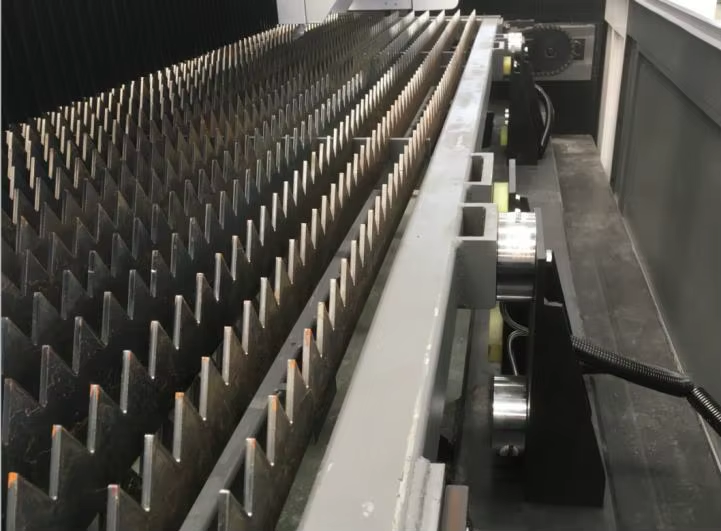

Each 240KG capacity, 4 of them. After exchange,the table is fixed well, no shaking under cutting.

Auto-lock function, cables never lose.

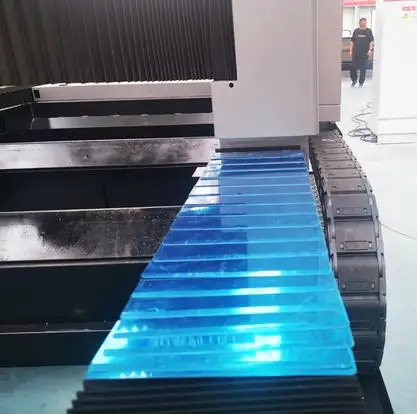

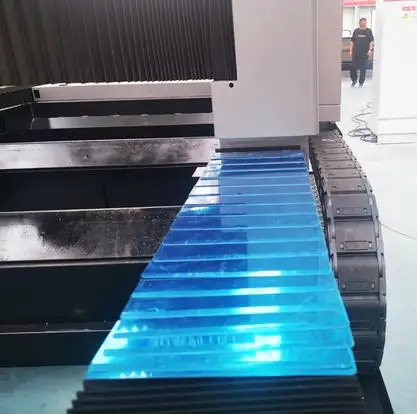

Plastic cover is to protect the guide rails,rack and pinions,etc,it can prevent heat,dust,however cutting fires,flames can burn it,we add one telescopic metal cover to protect plastic cover,that is double protection.

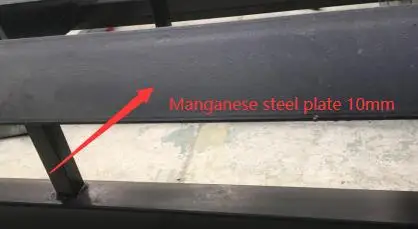

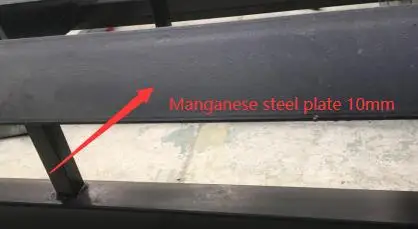

We add 10mm Manganese steel plate on the machine bed structure to avoid cutting flames or cutting hot slags on machine bed and having heat-affected on machine bed. Machine bed never shape changing or be damaged by high laser power.

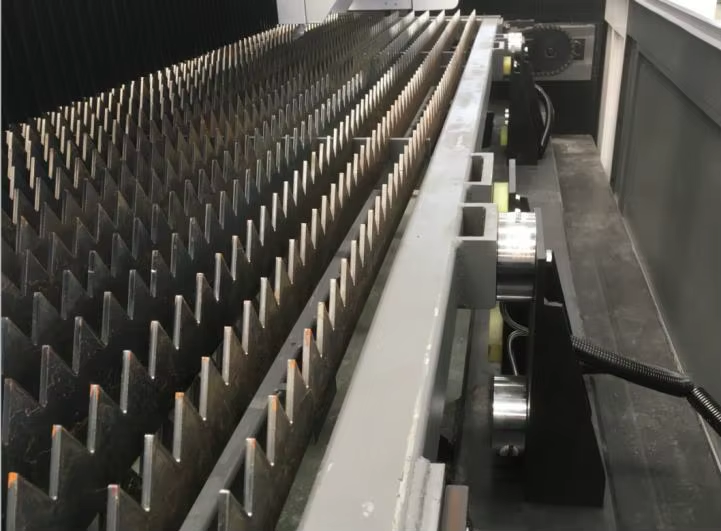

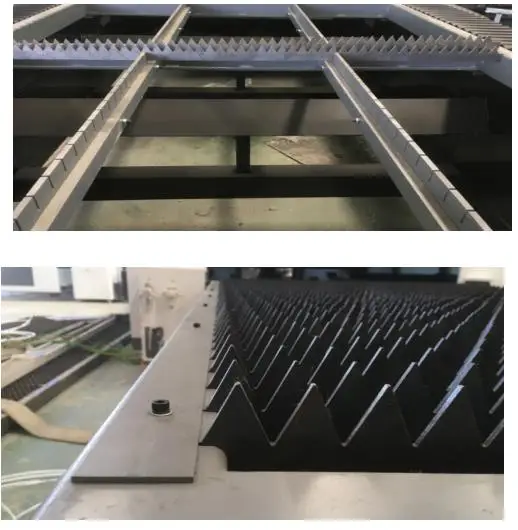

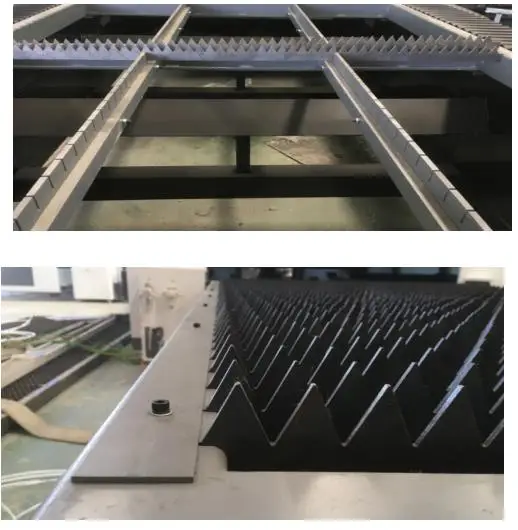

Blade saws holding fixture using manganese steel,blade saws never falling down. We use 3.75mm on 2kw power,can use longer time,and will be not shaking under fast cutting. others only use 1.5-2mm. We add blade saws clamping parts on machine bed,after install the blade saws,we screw it by clamping fixture, never shaking under cutting.

| Name | Time Hours |

| Protective mirror | 300-500 hours |

| Nozzle | 300-500 hours |

| Ceramic Rings | 4000 hours |

| Focus lens | 4000 hours |

Laser power: 1500W 2000W 3000W 6000W 8000W 10000W 12000W 20000W

Laser source brand:Max/Raycus/Jpt/Reci(optional)

Cooling system:water cooling

Application:stainless steel plates, carbon steel plates, galvanized sheets, ect

Features:

1. Support groove cutting, double chuck clamping, suitable for all kinds of irregular pipe fittings.

2. Flexible track is rough to steel pipe and has strong adaptability to deformation. Highly integrated.long service life, high efficiency and energy saving design can greatly save costs.

3. Set cutting plate, cutting pipe as one, can process all kinds of metal materials and all kindsof pipe fitting plate; Full intelligent CNC system, simple operation.

| Fiber Laser source | BWT / MAX laser source |

| Machine body | Plate welding machine bed with Heat-treatment |

| Laser Head | Raytools / Ospri laser head Autofocus |

| Motors and Drivers | Yaskawa |

| Reducer | Shimpo |

| System | FSCUT 3000S + CYPCUT software + Industrial CPU |

| Air control | SMC |

| Guide rail | HIWIN |

| Rack & pinion | Taiwan YYC |

| Water chiller | Hanli / S&A |

| Electrical components | Schneider |

| Transmission system | Dual-drive, precise rack and pinion |

| Exhaust fan | Included |

| Material | 3000W | Auxiliary gas |

| SS plate | ≤10 mm | Nitrogen |

| Carbon steel plate | ≤20 mm | Oxygen |

| Aluminum | ≤8 mm | Nitrogen |

| Brass | ≤6 mm | Nitrogen |

| Material | 3000W | Auxiliary gas |

| SS tube | ≤6 mm | Nitrogen |

| Iron tube | ≤10 mm | Oxygen |

| Aluminum tube | ≤6 mm | Nitrogen |

| Cutting range | 3000*2000mm / 4000*2000mm / 6000*2500mm |

| Laser power | 1500W / 2000W / 3000W / 6000W / 12000W |

| X/Y axis Repeated Position Precision | ±0.02mm |

| Max. Running Speed | 100r/min |

| Max. accelerated speed | 1.0G |

| Max. Load on working table | 800 KGS |

| Voltage | 3PHASE, 380V |

| Frequency | 50Hz/60Hz |

Durable pneumatic chuck enables high clamping accuracy, strong clamping force and stable performance.

We have milling machine in our factory for elaborate process of machine bed and parts in short time with great precision control.

Every machine body need to go through the 800 degree high-temperature quenching to make the machine body strong and stable, which is used by most reputational laser manufactory, such as TRUMPF, Trotec etc.

Each 240KG capacity, 4 of them. After exchange,the table is fixed well, no shaking under cutting.

Auto-lock function, cables never lose.

Plastic cover is to protect the guide rails,rack and pinions,etc,it can prevent heat,dust,however cutting fires,flames can burn it,we add one telescopic metal cover to protect plastic cover,that is double protection.

We add 10mm Manganese steel plate on the machine bed structure to avoid cutting flames or cutting hot slags on machine bed and having heat-affected on machine bed. Machine bed never shape changing or be damaged by high laser power.

Blade saws holding fixture using manganese steel,blade saws never falling down. We use 3.75mm on 2kw power,can use longer time,and will be not shaking under fast cutting. others only use 1.5-2mm. We add blade saws clamping parts on machine bed,after install the blade saws,we screw it by clamping fixture, never shaking under cutting.

| Name | Time Hours |

| Protective mirror | 300-500 hours |

| Nozzle | 300-500 hours |

| Ceramic Rings | 4000 hours |

| Focus lens | 4000 hours |