- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 3 Author: Site Editor Publish Time: 2026-01-15 Origin: Site

The ink blocking the cells affects the printing quality, which is a pain point that the flexo printing industry has been difficult to solve.

The anilox rollers that have been working for a long time, in addition to part of the damage caused by wear and tear, will also be scrapped due to the reduced cell volume, which affects the printing efficiency and quality. Deep cleaning at least 1-2 times a year will restore the anilox roller as new, prolong the service life of the anilox roller, improve printing quality, and reduce ink loss.

Laser cleaning can penetrate into meshes of any shape and size, especially suitable for high-line count anilox rollers. It can realize the recovery of cell volume without damaging the mesh wall, no consumables and no pollution, and the vaporized ink can also be recycled, which can extend the service life of the anilox roller and is low-carbon and environmentally friendly. Compared to traditional chemical cleaning, it saves the cost of consumables and labors, which can save a lot of costs for enterprises in the long run. Based on this, laser cleaning anilox rollers has gradually become the mainstream cleaning solutions.

DOYA Laser is committed to providing professional cleaning solutions for ceramic rollers in the corrugated-, flexo-, label- and offset printing industry. After several rounds of upgrades, DOYA ceramic anilox laser cleaning machine has

reached the technological level of the same type of products in Europe, filling the gap that China's anilox laser cleaning

equipment relies on imports.

The anilox laser cleaning machine becomes the standard equipment of the flexo printing workshop, which is the mission and vision of DOYA.

Advantages of Laser Cleaning Machine for Anilox Rollers

1. Tops all other methods in cleaning result

2. Consistent highest printing quality

3. Increases Anilox lifetime

4. Removes all types of residues and dirt

5. Effective restoring cell volume and surface tension

6. Reduce downtime and labour time for cleaning

7. No use of water, chemicals or granulates

8. Easy to use: fully automated and maintenance light

9. Most environmental friendly method

Unmatched Printing Quality and Sustainability of Laser Cleaning

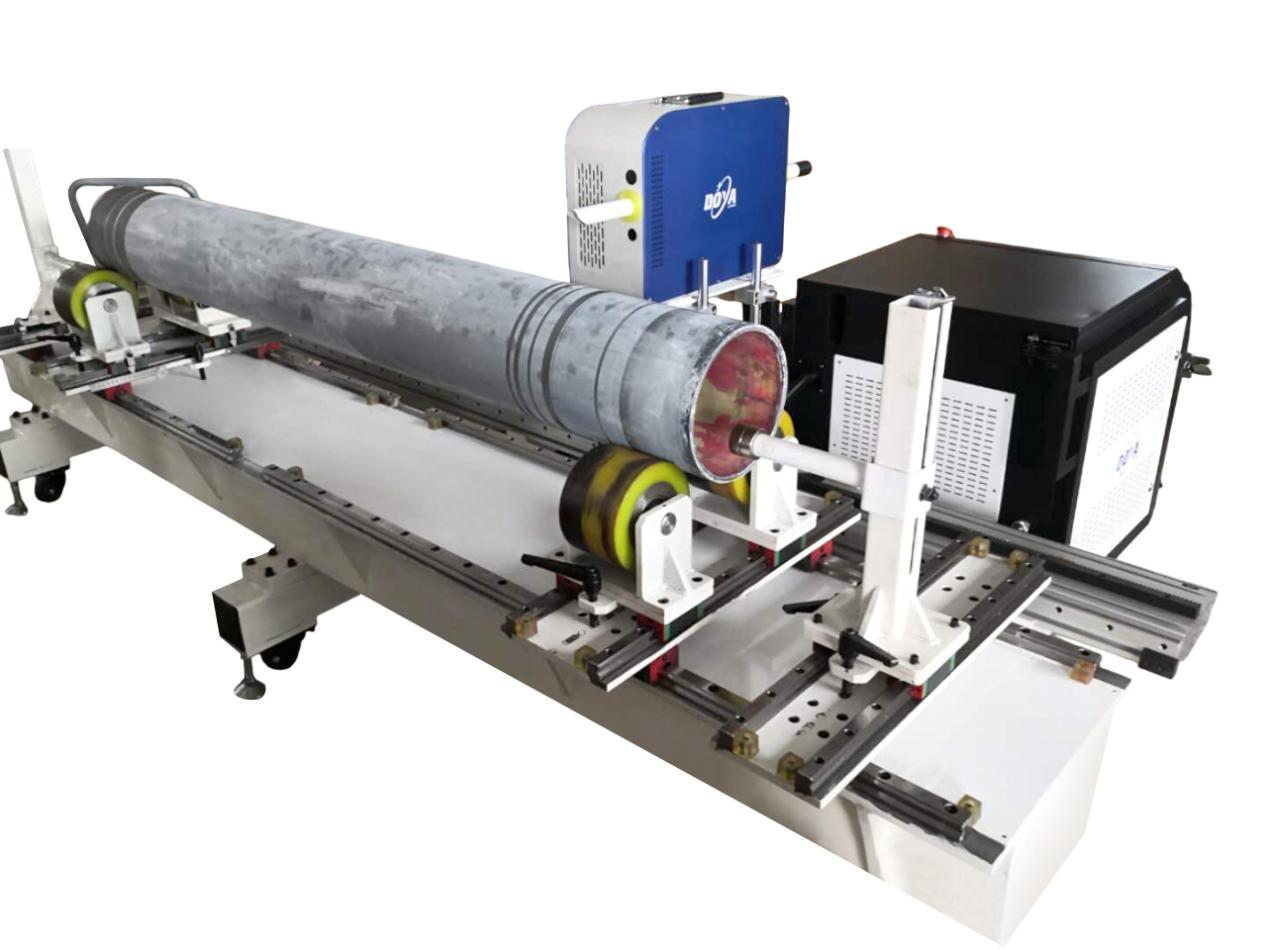

All ACL machines have the same cleaning process: the roller is being driven and turns, while the laser gun is being moved from left to right, parallel to the dirty roller. The energy of the laser beam is absorbed by the pollution, which consists of pigments and polymers, and then disintegrates. The laser beam is enough powerful to remove the pollution but doesn’t possess the power to damage the ceramic surface of the roller. After laser cleaning cell volume and surface tension are fully restored and the roller can be immediately used for printing.

Laser cleaning is the most controlled and efficient way to clean anilox surfaces, resulting in the highest constant printing quality.

Laser cleaning is based on indirect contact. the roller isn’t touched other than by the laser beam. No granulates, chemicals or water are needed.

ACL laser cleaning machines offer the most sustainable and environmental friendly cleaning method for anilox rollers.

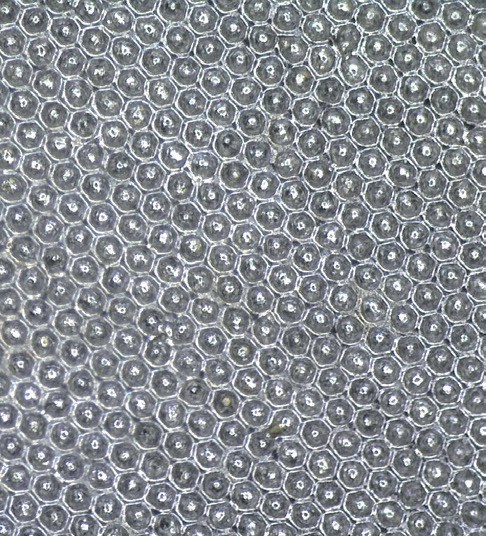

Before laser cleaning After laser cleaning

Enclosed Type Laser Cleaning Machine for Anilox Rollers

ACL1200 is especially suitable for cleaning narrow anilox rollers, especially rollers on label printing machines. Both the label roller and the sleeve can be easily cleaned.

There is no need to disassemble gears and bearings during the cleaning process, and the cleaned roller can be used for printing at once.

ACL2000 is suitable for off-line cleaning of medium-sized anilox rollers or sleeves, with a maximum length of 2000mm (The sides of the cabinet can be opened, so there's no need to worry even if the shaft length exceeds 2 meters).

Only need to input the relevant data of the anilox roller and press the power button to automatically complete the cleaning, no consumables, environmental protection and high efficiency.

This cleaning equipment has strong compatibility and can meet most of the regular size rollers cleaning needs. It is suitable for medium and large printing workshops, so that laser cleaning can be used regularly, the anilox roller is always in a new state and the printing quality is always at an excellent level.

Mobile Type Laser Cleaning System for Anilox Rollers

ACLM Mobile Laser Cleaning System is suitable for cleaning large anilox rollers for corrugated packaging paper printing. No matter how weight or big size anilox rollers are, they can be easily cleaned.

It can be used both in a service truck or static setup, as well as in-press.

Especially corrugated printers rely on in-press laser cleaning service for professional periodic deep cleaning of their Anilox rollers.

This equipment can clean online without disassembling the anilox roller, which solves the pain points of time-consuming and laborious disassembly and assembly of large anilox rollers. If you are a service provider engaged in cleaning services, this equipment can meet the needs of most of your customers.

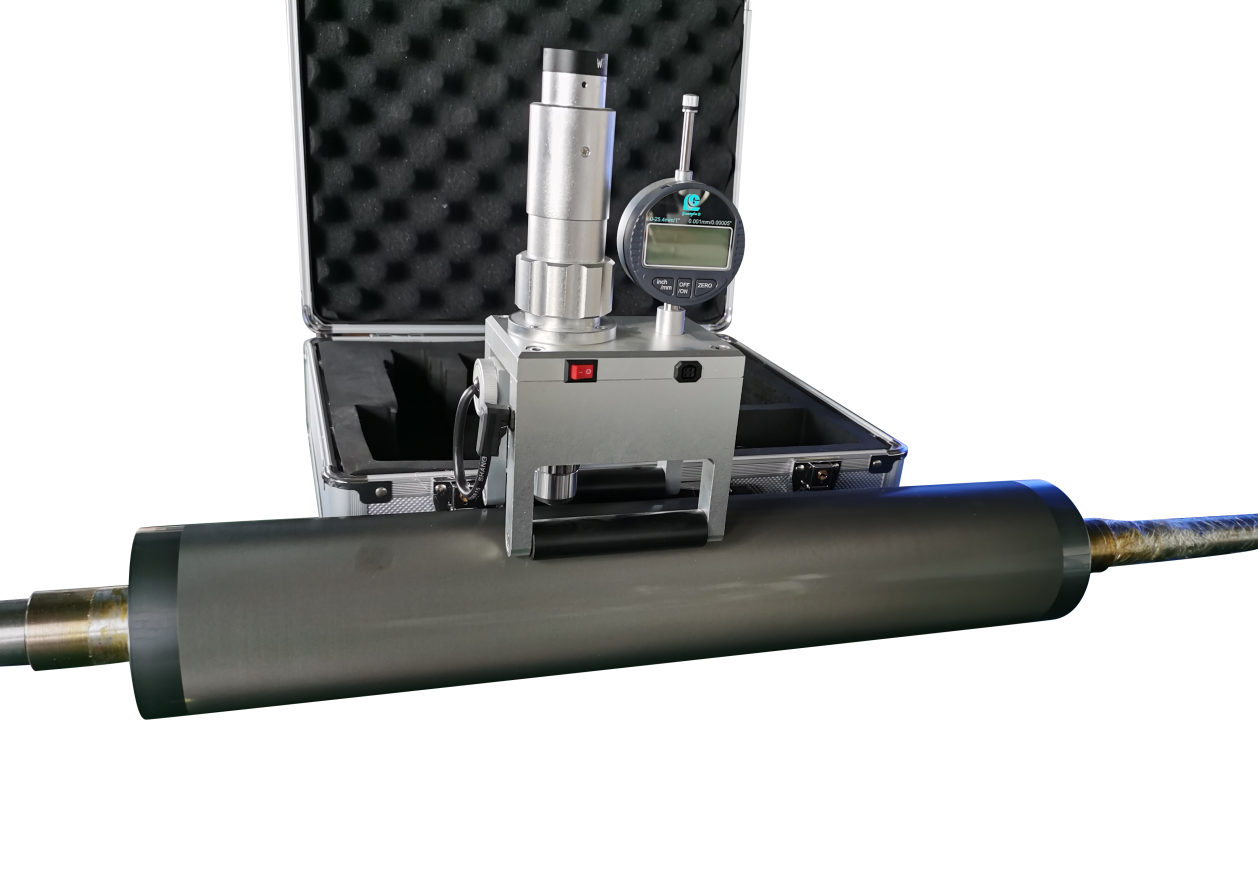

ACL-Micro Cell Inspection Instrument for Anilox Rollers

The anilox roll cell inspection instrument is also called a depth microscope,or anilox roll optical zoom microscope,which can be used to measure the line count of the ceramic anilox roll,the thickness of the mesh wall and the depth of the cell.

The inspection instrument has a built-in low-power optical illumination system and a height-measuring gauge,and a minimum resolution of 0.005mm/div.The instrument can be equipped with a digital camera,which is convenient for data processing with computer and convenient for storage and management.It can be used as a special testing instrument for anilox rollers and can be used in other industries as testing work.The microscope provides two magnifications of 200 and 400 as options.

FAQ

1. Does the laser burn away all the ink in the cells?

No, the primary reason for cleaning is not based on thermodynamic principles. The short laser pulse has extremely high peak power, and the powerful burst force breaks the adhesion between the ink and the ceramic, removing dirt from the roller holes. It also generates minimal heat accumulation, reducing the risk of damage to the anilox roller.

2. Will it damage the ceramic surface of the roller?

No, our method for cleaning anilox rollers is safe. The optical path and motion control logic are optimized specifically for cleaning ceramic anilox rollers, designed to avoid damaging the substrate.

With traditional laser source, damage to the ceramic layer is unavoidable. To confirm the safety of laser cleaning, we use the special design, and we magnify each roll of anilox roller after cleaning 400 times to observe whether the cleaning process caused any damage.

3. Will it damage the mesh walls of high-line-count anilox rollers?

No, we will not damage the mesh walls. The laser beam heats the ink to 400-600 degrees Celsius, far below the 1500 degrees Celsius melting point of ceramics when laser engraving the roller surface.

4. Can an anilox roller be laser cleaned multiple times?

Yes, our customers deep clean their anilox rollers 1-2 times a year (provided that routine anilox roller cleaning and maintenance are proper). Multiple laser cleanings will not damage the anilox roller.

5. How long does the laser cleaning effect last?

During the laser cleaning process, the dirt at the bottom of the cells is exposed. After laser cleaning, the roller's function can be restored to that of a new roller.

6. Do you provide cleaning services?

We are an equipment manufacturer, primarily selling products. We can clean one anilox roller for customer free of charge to test the effect.

7. Can the cells be repaired?

No, wear and mechanical damage that occurred before cleaning is irreversible.