- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

DFC-3000

DOYA

8456110090

Laser power: 1000W 1500W 3000W 6000W 8000W 10000W 12000W 20000W

Laser source brand: Max/Raycus/Jpt/Reci(optional)

Cooling system: water coolingApplication: stainless steel plates, carbon steel plates, galvanized sheets, ect

Features:

1. Cutting speed is fast, more than 100 times that of wire cutting.

2. Fiber laser cutting machine has high precision and is suitable forcutting precision accessories.

3. Small heat-affected area, stable performance, ensure continuous production, not easy todeformation, smooth slit, beautiful, no post-processing and other advantages.

| Fiber Laser source | BWT / MAX laser source |

| Gantry | Aviation Aluminum |

| Laser Head | Raytools / Ospri laser head Autofocus |

| Motors and Drivers | LEAD / JAPAN FUJI |

| Reducer | Shimpo / Japan Beitto |

| System | Cypcut with height controller |

| Guide rail | FXDF / Taiwan SLOPES |

| Rack & pinion | LST / Taiwan YYC |

| Water chiller | Hanli / S&A |

| Air control | Can change gas in software, Japan SMC |

| Electrical components | Schneider |

| Auto lubrication | Included |

| Exhaust fan | Included |

| Machine Outlook | Open model |

| Machine weight | 2.5 T |

| Material | SS plate | Carbon steel plate | Aluminum | Brass |

| 3000W | ≤10 mm | ≤20 mm | ≤8 mm | ≤6 mm |

| 6000W | ≤16 mm | ≤26 mm | ≤12 mm | ≤10 mm |

| Auxiliary gas | Nitrogen | Oxygen | Nitrogen | Nitrogen |

| Machine model | DFC-H1530 |

| Working area (L*W) | 3000*1500mm |

| X/Y axis Repeated Position Precision | ±0.02mm |

| Max. Running Speed | 100m/min |

| Max. accelerated speed | 1.0G |

| Max. Load on working table | 800 KGS |

| Voltage | 3PHASE, 380V |

| Frequency | 50Hz/60Hz |

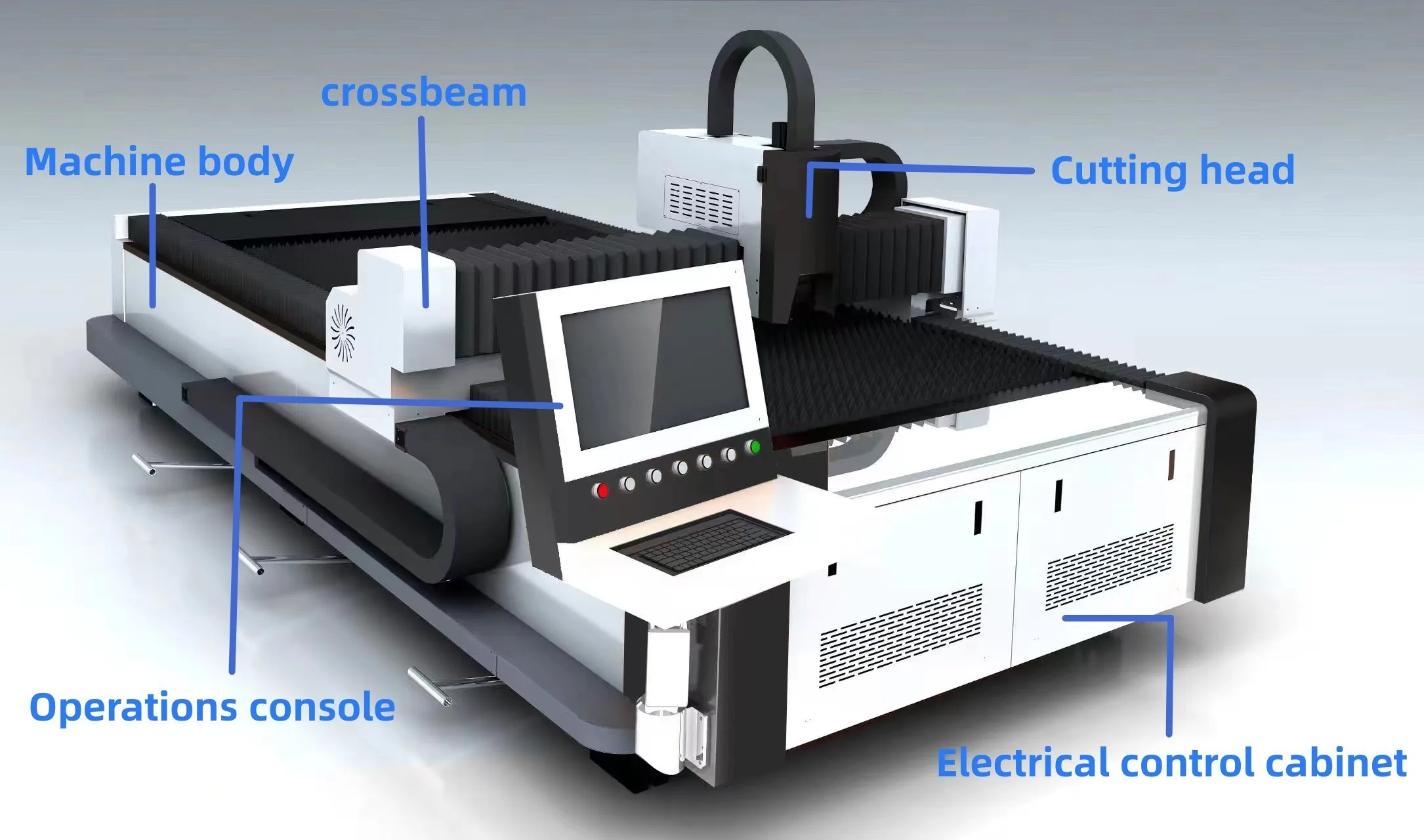

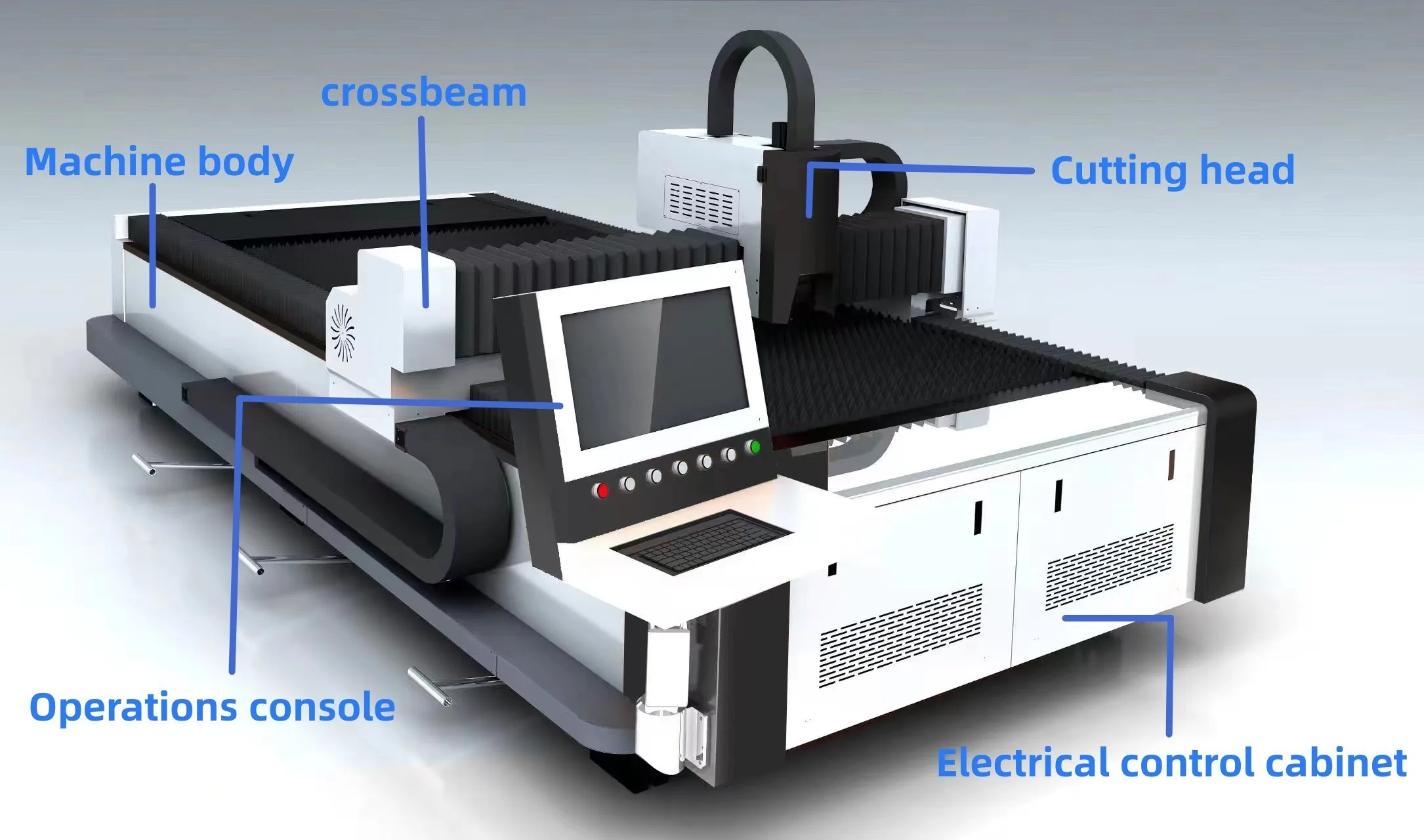

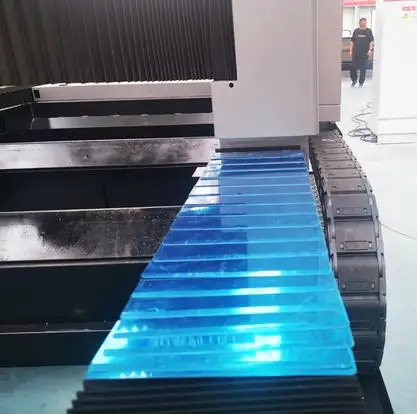

The machine body use thick tube welding machine body, stable and strong. Machine body is stable, which ensures pefect cutting effect even fast speed operation.

It is not easy to deform, even can use more than 10 years.

Every machine body need to go through the 800 degree high-temperature quenching to make the machine body strong and stable, which is used by most reputational laser manufactory, such as TRUMPF, Trotec etc.

Integrated laser cutting special function module, powerful function, good man-machine interface, simple operation, easy to learn and understand. Compatible with a variety of CAD, DXF, AI, IGS drawing formats, intelligent discharging and saves costs, automatic cutting path matching saves processing time.

Ospri with autofocus function The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. Piercing is fast.

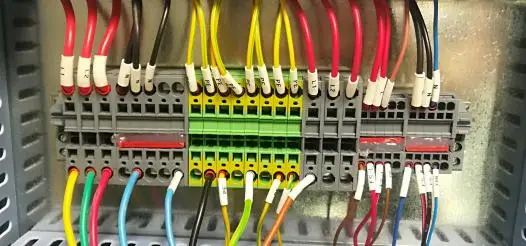

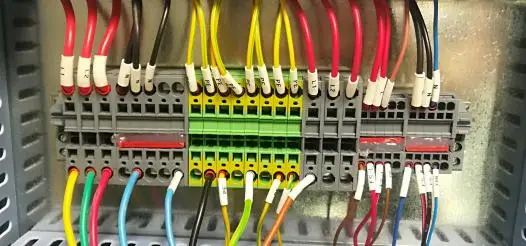

Schneider brand It has auto-lock function, cables never lose.

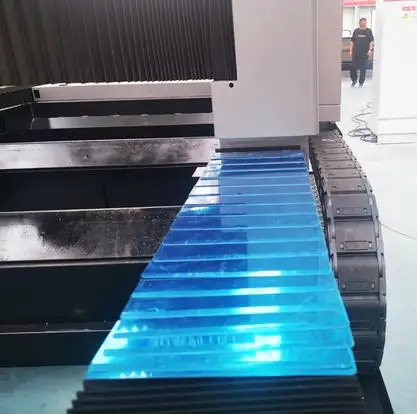

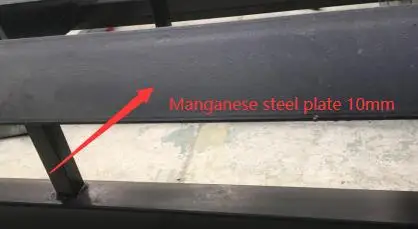

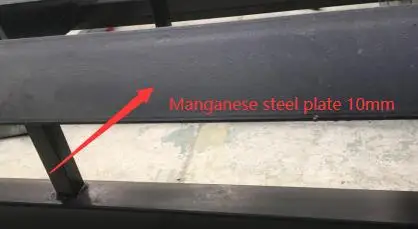

We add 10mm Manganese steel plate on the machine bed structure to avoid cutting flames or cutting hot slags on machine bed and having heat-affected on machine bed. Machine bed never shape changing or be damaged by high laser power.

Blade saws are stable and thicker

| Name | Time Hours |

| Protective mirror | 300-500 hours |

| Nozzle | 300-500 hours |

| Ceramic Rings | 4000 hours |

| Focus lens | 4000 hours |

Laser power: 1000W 1500W 3000W 6000W 8000W 10000W 12000W 20000W

Laser source brand: Max/Raycus/Jpt/Reci(optional)

Cooling system: water coolingApplication: stainless steel plates, carbon steel plates, galvanized sheets, ect

Features:

1. Cutting speed is fast, more than 100 times that of wire cutting.

2. Fiber laser cutting machine has high precision and is suitable forcutting precision accessories.

3. Small heat-affected area, stable performance, ensure continuous production, not easy todeformation, smooth slit, beautiful, no post-processing and other advantages.

| Fiber Laser source | BWT / MAX laser source |

| Gantry | Aviation Aluminum |

| Laser Head | Raytools / Ospri laser head Autofocus |

| Motors and Drivers | LEAD / JAPAN FUJI |

| Reducer | Shimpo / Japan Beitto |

| System | Cypcut with height controller |

| Guide rail | FXDF / Taiwan SLOPES |

| Rack & pinion | LST / Taiwan YYC |

| Water chiller | Hanli / S&A |

| Air control | Can change gas in software, Japan SMC |

| Electrical components | Schneider |

| Auto lubrication | Included |

| Exhaust fan | Included |

| Machine Outlook | Open model |

| Machine weight | 2.5 T |

| Material | SS plate | Carbon steel plate | Aluminum | Brass |

| 3000W | ≤10 mm | ≤20 mm | ≤8 mm | ≤6 mm |

| 6000W | ≤16 mm | ≤26 mm | ≤12 mm | ≤10 mm |

| Auxiliary gas | Nitrogen | Oxygen | Nitrogen | Nitrogen |

| Machine model | DFC-H1530 |

| Working area (L*W) | 3000*1500mm |

| X/Y axis Repeated Position Precision | ±0.02mm |

| Max. Running Speed | 100m/min |

| Max. accelerated speed | 1.0G |

| Max. Load on working table | 800 KGS |

| Voltage | 3PHASE, 380V |

| Frequency | 50Hz/60Hz |

The machine body use thick tube welding machine body, stable and strong. Machine body is stable, which ensures pefect cutting effect even fast speed operation.

It is not easy to deform, even can use more than 10 years.

Every machine body need to go through the 800 degree high-temperature quenching to make the machine body strong and stable, which is used by most reputational laser manufactory, such as TRUMPF, Trotec etc.

Integrated laser cutting special function module, powerful function, good man-machine interface, simple operation, easy to learn and understand. Compatible with a variety of CAD, DXF, AI, IGS drawing formats, intelligent discharging and saves costs, automatic cutting path matching saves processing time.

Ospri with autofocus function The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. Piercing is fast.

Schneider brand It has auto-lock function, cables never lose.

We add 10mm Manganese steel plate on the machine bed structure to avoid cutting flames or cutting hot slags on machine bed and having heat-affected on machine bed. Machine bed never shape changing or be damaged by high laser power.

Blade saws are stable and thicker

| Name | Time Hours |

| Protective mirror | 300-500 hours |

| Nozzle | 300-500 hours |

| Ceramic Rings | 4000 hours |

| Focus lens | 4000 hours |