- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| power: | |

|---|---|

| Availability: | |

| Quantity: | |

DHWM

DOYA

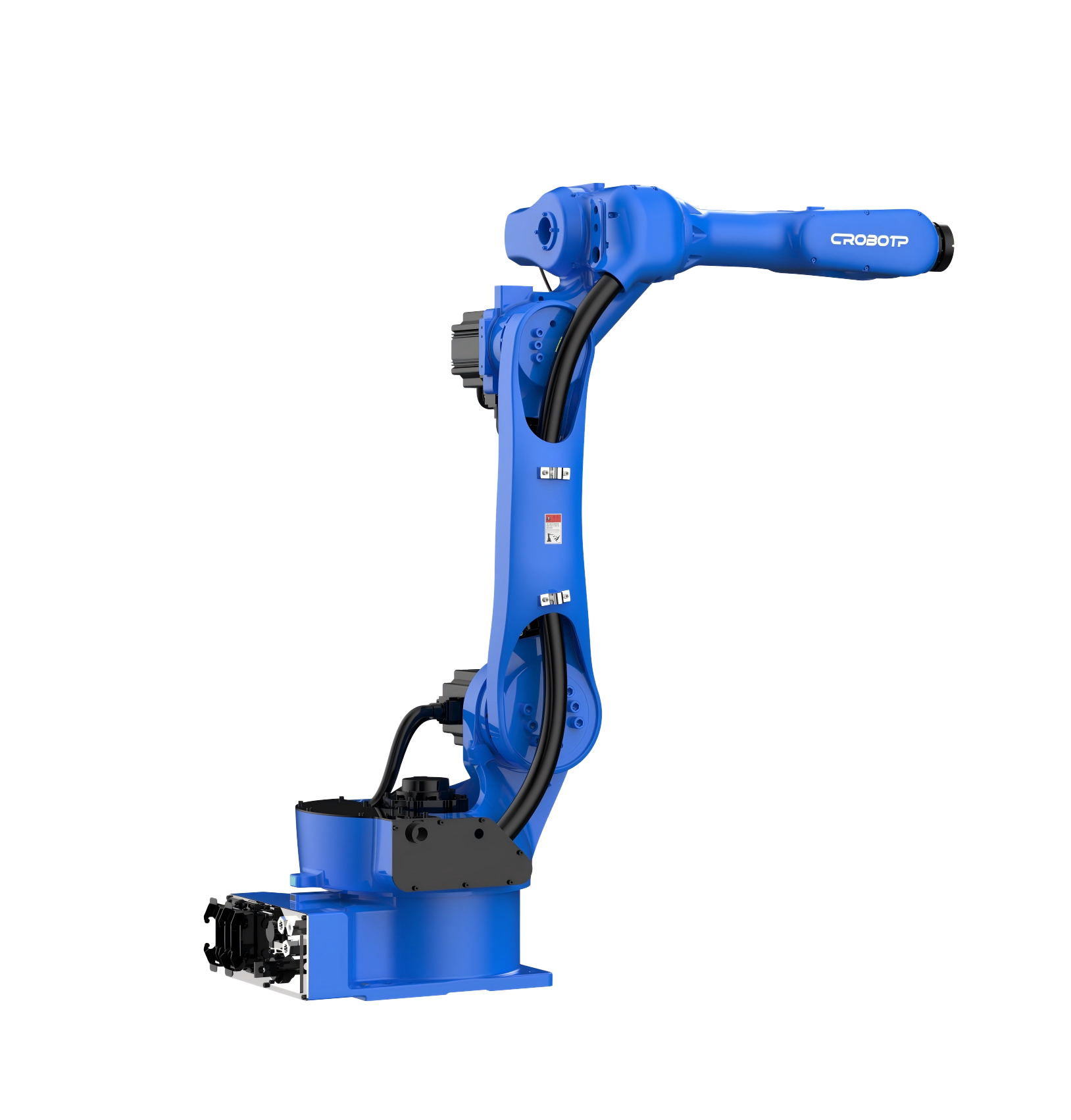

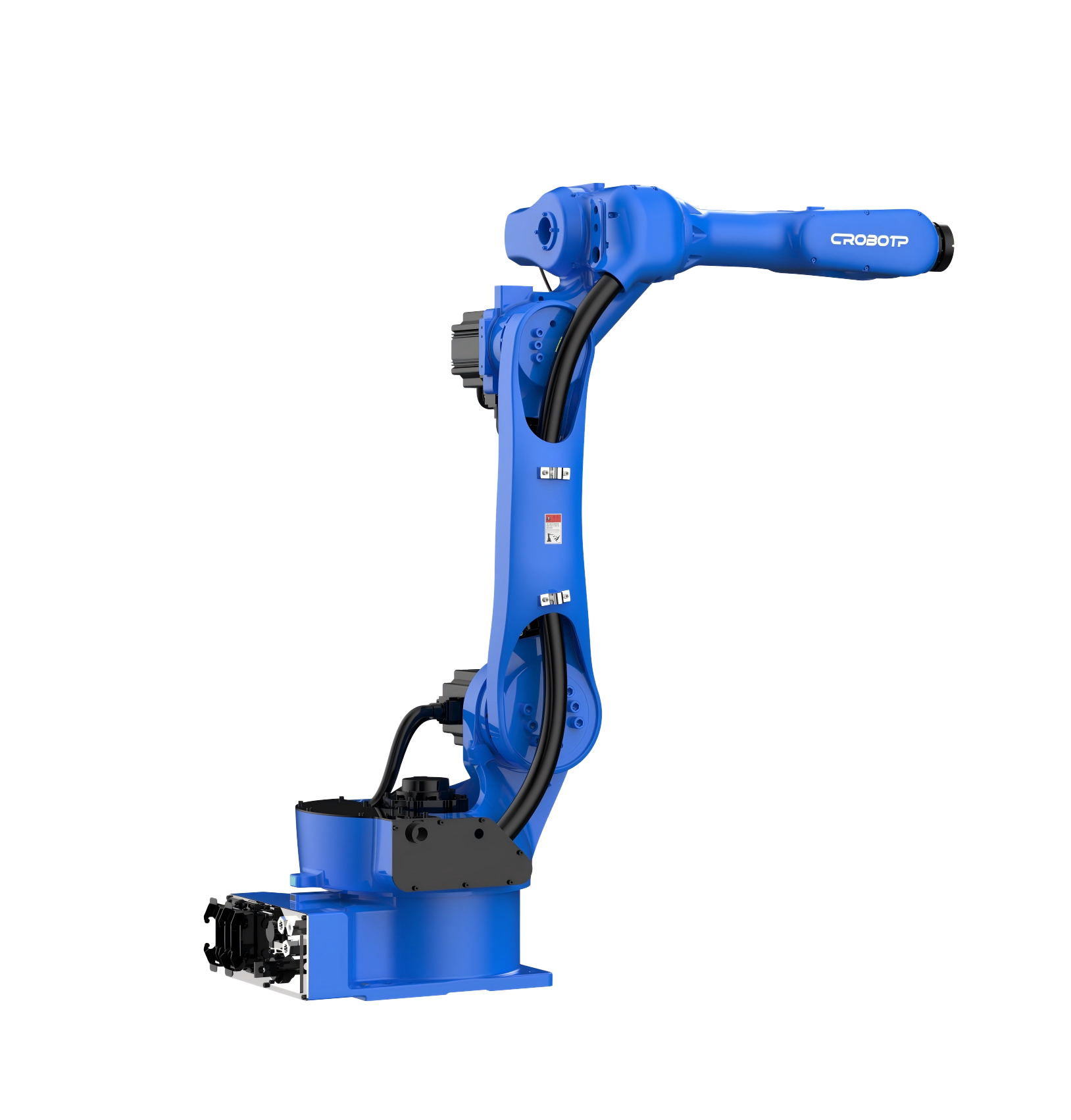

Robot Laser Welding Machine

Six-axis robot laser welding machine is the most typical robot laser welding machine,which combine speed,payload capacity,and reach.The robots can cover most laserwelding applications.Itspecializes in medium to large-sized welding tasks.Its excellentrange of motion helps weld complex part geometries.

Robot welding equipment in the welding market can select appropriate weldingparameters to apply to workpieces of different specifications and materials accordingto different application fields.

It can play a greater role in welding workand complete welding work.

It is widely used in engineering machinery manufacturing, automobile manufacturing, electronics industry, municipal construction, shipbuilding and other fields.

Robot Laser Welding Machine

Six-axis robot laser welding machine is the most typical robot laser welding machine,which combine speed,payload capacity,and reach.The robots can cover most laserwelding applications.Itspecializes in medium to large-sized welding tasks.Its excellentrange of motion helps weld complex part geometries.

Robot welding equipment in the welding market can select appropriate weldingparameters to apply to workpieces of different specifications and materials accordingto different application fields.

It can play a greater role in welding workand complete welding work.

It is widely used in engineering machinery manufacturing, automobile manufacturing, electronics industry, municipal construction, shipbuilding and other fields.

Product Advantages

Welding robot can work in harmful environment

It can runs 24 hours,and greatly improve the production efficiency.

Stabilize and improve the welding quality of work pieces.

Reduced requirements for workers to operate skills.

Save materials,costs and energy.

Functional Features

The design is highly compact and can be flexibly installed on the ground or upside down.

With large working space,fast running speed and high repeated positioning accuracy.It is suitable for a wide range of welding applications.

It is equipped with a safety emergency stop board independent of the control system.

The robot body adopts highly flexible special cable.

Built-in three-phase transformer makes 380V and 220V isolated to help thepower supply more stable.Built-in three-phase filter can effectively improve theperformance of EMC and EMI.

Product Details

Laser Welding Robot+Controller

Laser welding special interface,controllable power output,wire feed,slow rise and slow fall,pre-ignition and attenuation,adhesion detection,pre-ignition drawing and filling,etc.

Strong rigidity,high precision,low jitter.

Servo or stepper motor wire feed can be controlled.The robot is programmed more efficiently by using the vertical demonstrator.

Small electric cabinet,small size,can be integrated into the laser host.

Single-phase 220V input power supply,easyaccess.

With UPS,support power failure regeneration.

Laser Welding Head

With push-pullwire function,dual motor controlto prevent wire sticking,with high precision of±0.2mm.

Anti-collision:When the collision resistance is greater than 500g,an emergency stop alarm will be triggered to protect the laser head,and the anti-collision reset accuracy is±0.1mm.

The integrated wire feeding copper nozzle eliminates the traditional wire feeding mechanism,resulting in a smaller volume and reduced interference.

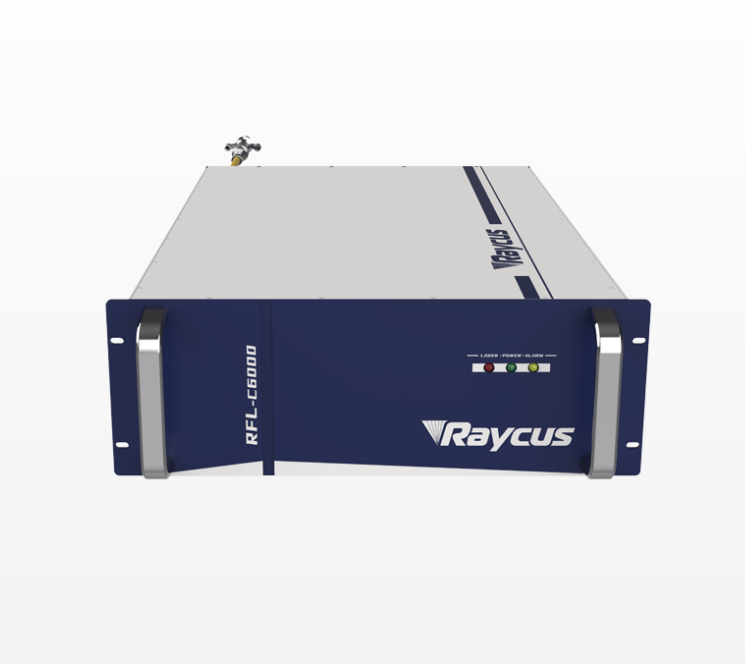

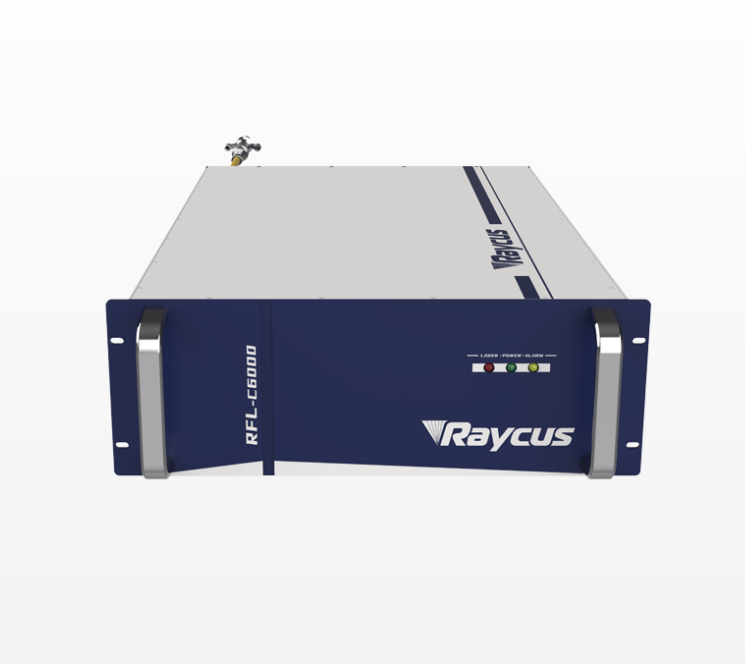

Raycus/Max Laser source

Stable performance.China's famous laser brand,continuous fiber laser.

Product Advantages

Welding robot can work in harmful environment

It can runs 24 hours,and greatly improve the production efficiency.

Stabilize and improve the welding quality of work pieces.

Reduced requirements for workers to operate skills.

Save materials,costs and energy.

Functional Features

The design is highly compact and can be flexibly installed on the ground or upside down.

With large working space,fast running speed and high repeated positioning accuracy.It is suitable for a wide range of welding applications.

It is equipped with a safety emergency stop board independent of the control system.

The robot body adopts highly flexible special cable.

Built-in three-phase transformer makes 380V and 220V isolated to help thepower supply more stable.Built-in three-phase filter can effectively improve theperformance of EMC and EMI.

Product Details

Laser Welding Robot+Controller

Laser welding special interface,controllable power output,wire feed,slow rise and slow fall,pre-ignition and attenuation,adhesion detection,pre-ignition drawing and filling,etc.

Strong rigidity,high precision,low jitter.

Servo or stepper motor wire feed can be controlled.The robot is programmed more efficiently by using the vertical demonstrator.

Small electric cabinet,small size,can be integrated into the laser host.

Single-phase 220V input power supply,easyaccess.

With UPS,support power failure regeneration.

Laser Welding Head

With push-pullwire function,dual motor controlto prevent wire sticking,with high precision of±0.2mm.

Anti-collision:When the collision resistance is greater than 500g,an emergency stop alarm will be triggered to protect the laser head,and the anti-collision reset accuracy is±0.1mm.

The integrated wire feeding copper nozzle eliminates the traditional wire feeding mechanism,resulting in a smaller volume and reduced interference.

Raycus/Max Laser source

Stable performance.China's famous laser brand,continuous fiber laser.

Technical Parameters of Robot Laser Welding Machine

| Power Parameters | 1500W | 2000w | 3000W |

| Power Consumption | s6000W | ≤7500W | ≤9000W |

| Laser Source | Raycus/Max/BWT (optional) | ||

| Wingspan | 1500-1800mm | ||

| Working Mode | Robot/Automatic | ||

| Diameter of Fiber Core | 50um | ||

| Adjustment Range of Power | 10-100% | ||

| Welding Spot | 0.1-5mm adjustable | ||

| Min Line Width | ≤0.15mm | ||

| Auxiliary Gas | Nitrogent | ||

| Fiber Connection | QBH | ||

| Optical Fiber Length | 10m(can be customized) | ||

| Suitable Material | Aluminum,carbon steel,stainles steel,copper,brass,galvanized sheet,etc. | ||

| Type of Welding Head | Dua motor push-pull vwire feed welding head,with anti-collision | ||

| Water Chiller | S&A/Hanli (optional) | ||

| Power Supply | AC 220V±10%,Single phase/380V±10%,3 phase;50/60Hz | ||

| Working Temperature | 0℃-40℃ | ||

| Size | 81*40*76cm | 108*45*81cm | 111*53*91cm |

| Weight | 105kg | 115kg | 160kg |

Robot Body Technical Parameters

| Model | RA15-12-J | RA18-20-J | RA20-12-J |

| Degree of freedom | 6 | 6 | 6 |

| Maximum payload | 12kg | 20kg | 12kg |

| Maximum reaching distance | 1554mm | 1821mm | 2015mm |

| Repeated positioning accuracy | ±0.05mm | ±0.05mm | ±0.08mm |

| Installation environment | Temperature:0~45°,humidity:20%~80%(no condensation) | ||

| Robot body weight | 170kg | 288kg | 262kg |

| installation mode | Formal/upside down/wall hanging | ||

| IP level | Robot body IP54 Wrist IP67 | ||

Technical Parameters of Robot Laser Welding Machine

| Power Parameters | 1500W | 2000w | 3000W |

| Power Consumption | s6000W | ≤7500W | ≤9000W |

| Laser Source | Raycus/Max/BWT (optional) | ||

| Wingspan | 1500-1800mm | ||

| Working Mode | Robot/Automatic | ||

| Diameter of Fiber Core | 50um | ||

| Adjustment Range of Power | 10-100% | ||

| Welding Spot | 0.1-5mm adjustable | ||

| Min Line Width | ≤0.15mm | ||

| Auxiliary Gas | Nitrogent | ||

| Fiber Connection | QBH | ||

| Optical Fiber Length | 10m(can be customized) | ||

| Suitable Material | Aluminum,carbon steel,stainles steel,copper,brass,galvanized sheet,etc. | ||

| Type of Welding Head | Dua motor push-pull vwire feed welding head,with anti-collision | ||

| Water Chiller | S&A/Hanli (optional) | ||

| Power Supply | AC 220V±10%,Single phase/380V±10%,3 phase;50/60Hz | ||

| Working Temperature | 0℃-40℃ | ||

| Size | 81*40*76cm | 108*45*81cm | 111*53*91cm |

| Weight | 105kg | 115kg | 160kg |

Robot Body Technical Parameters

| Model | RA15-12-J | RA18-20-J | RA20-12-J |

| Degree of freedom | 6 | 6 | 6 |

| Maximum payload | 12kg | 20kg | 12kg |

| Maximum reaching distance | 1554mm | 1821mm | 2015mm |

| Repeated positioning accuracy | ±0.05mm | ±0.05mm | ±0.08mm |

| Installation environment | Temperature:0~45°,humidity:20%~80%(no condensation) | ||

| Robot body weight | 170kg | 288kg | 262kg |

| installation mode | Formal/upside down/wall hanging | ||

| IP level | Robot body IP54 Wrist IP67 | ||